The Only Guide to Aws Cwi

Little Known Questions About Aws Cwi.

Table of ContentsThe Best Guide To Aws CwiFacts About Aws Cwi RevealedGetting My Aws Cwi To WorkAn Unbiased View of Aws CwiAws Cwi for Dummies

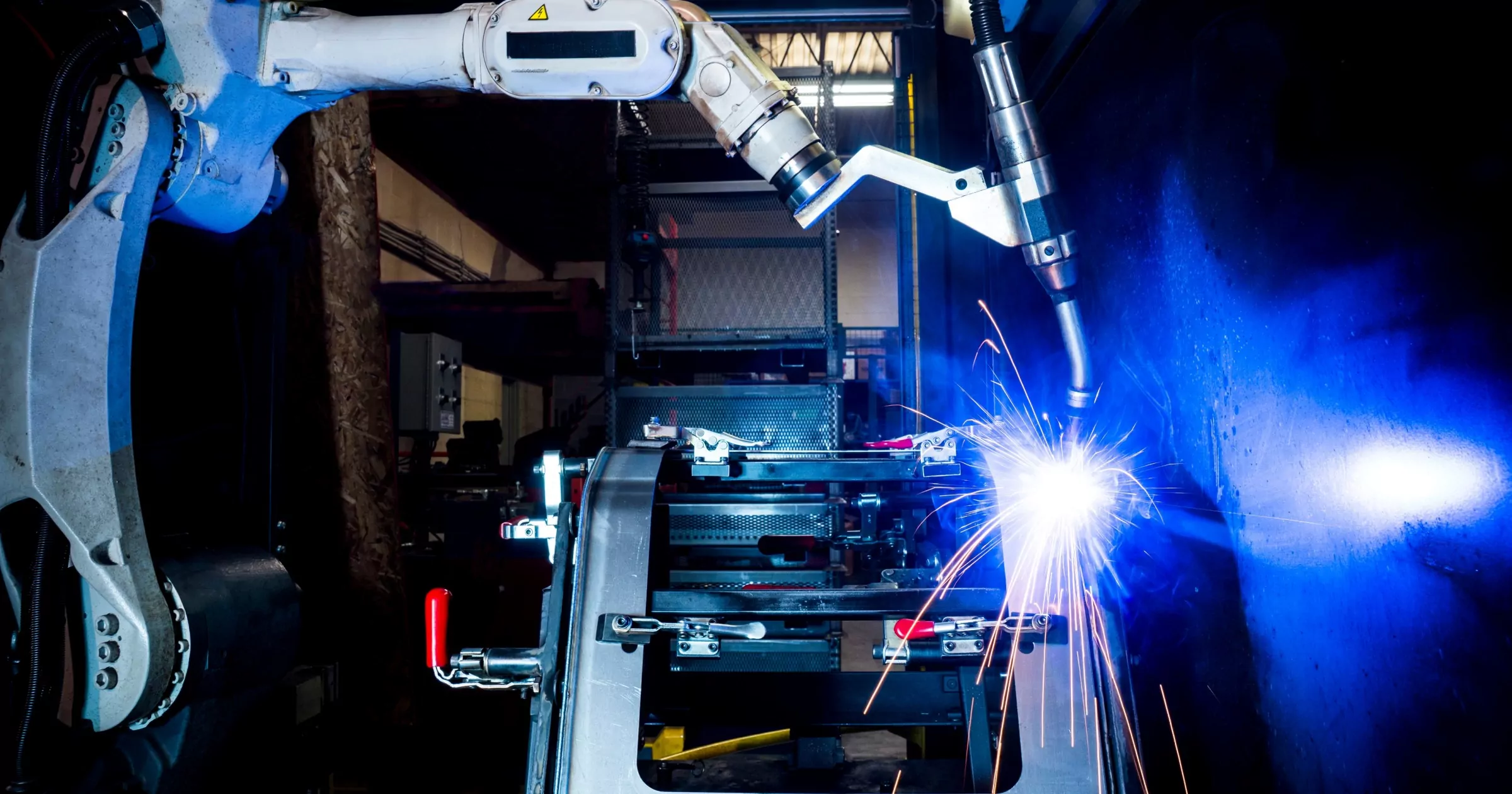

Third-party quality assurance inspection of steel construction facilities on welding evaluation, as well as examination of bolting and painting of architectural steel. KTA's steel examiners provide Quality assurance (QC) assessors to supplement fabricator's/ service provider's internal QC staff and on jobs that mandate keeping the solutions of a certified examiner (e.g., CWI) utilized by an independent assessment company.Inspectors conduct visual assessments of product for conformance with the accepted requirements, plans and codes, in addition to verification of Licensed Material Test Reports (CMTR) for products used. Materials and elements are observed at essential points along the production procedure in both steel mills and steel construction stores. KTA's qualified welding examiners also witness welder and welding procedure certification examinations as appropriate to the scope of the task.

Steel manufacture assessment solutions additionally consistently consist of doing non-destructive screening (NDT), additionally known as non-destructive evaluation (NDE), consisting of Magnetic Particle Testing (MT), Ultrasonic Screening (UT) and Fluid Penetrant Examining (PT). KTA's evaluation solutions consist of finish assessments covering surface area prep work, paint, galvanizing, and metalizing.

KTA's philosophy is to respond swiftly to customers' needs, match the best inspector to the task, and provide the requisite paperwork. KTA has the assistance workers to give technological consulting to the area personnel and to the client. KTA has professionals readily available to get in touch with on welding, NDT and finishings.

FST Technical Solutions is your international partner in the Semiconductor and Pharmaceutical Industries! Our positions consist of benefits such as medical, oral, vision, life, 401(k) with business suit, PTO, paid vacations. Come sign up with an awesome team in an amazing, rapid paced, and ever-growing industry! We are looking for a CWI's and/or NDT Degree II certified Welding Inspectors from around the Lithia Springs, GA area! Area prospects are urged to apply but this placement is open to tourists with mobilization and month-to-month daily for those living outside the area.

3 Simple Techniques For Aws Cwi

Ideal candidate will have high pureness piping assessment experience. CWI's and NDT Level II's highly motivated to apply.

Pro QC's third-party welding assessment solutions include: Document Review Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding evaluation reports are provided within 24 hours and document all evaluation factors relevant to quality, including all determined weld flaws and electronic photos (Certified Welding Inspector) (https://www.brownbook.net/business/53061049/aws-cwi/). Pro QC's group of assessors supplies third-party welding evaluations around the discover here world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the UK, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the USA, Mexico, copyright, Brazil, Peru, and many even more countries

Assessment of the welding job is important for proper top quality When your company is managing major tasks with demands for 3rd party independent welding assessment, we give superb welding witness examination solutions to confirm that welding has been executed according to most applied welding requirements and specs. AQSS does welding evaluation solutions for clients from a selection of sectors.

How Aws Cwi can Save You Time, Stress, and Money.

Not following appropriately certified welding treatments typically causes a weld of below average top quality, which can increase the construction's chance of failure under desired service conditions. By examining for issues, our assessors can help customers make certain that their welds fulfill relevant standards of quality control (Weld Inspector). Weld assessments are performed for numerous reasons, one of the most usual of which is to identify whether the weld is of appropriate high quality for its desired application

Our welding examiners have the called for accreditations with years of experience with evaluation and are acquainted with most applied welding standards and specifications. AQSS has CWI licensed examiners.

The 5-Second Trick For Aws Cwi

Generally, our inspectors are examining for cracks, pits, surface pores, undercut, underfill, missed joints, and various other facets of the weld.

Examples can also be taken at periods throughout the production procedure or at the end of the run. Harmful screening examples are exactly cut, machined, ground, and polished to a mirror-like coating. An acid etch is after that related to visually bring out the weld, and the sample is then examined under a microscope.